Full automatic cleaning

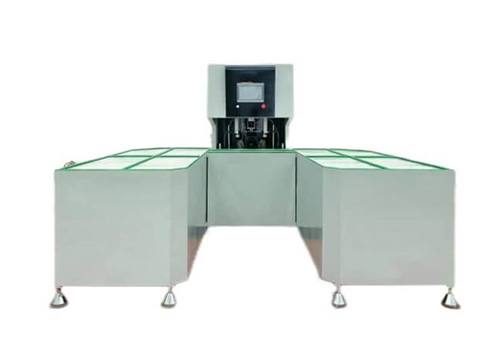

CNC corner cleaning machine 3 cutter scanning

Full automatic cleaning

The intelligent CNC corner cleaning machine is a special equipment used for cleaning 90-degree angle seam welding slag of plastic steel doors and windows. The equipment uses an industrial computer as the hardware hub and the world’s most advanced human-machine interface LED LCD touch operation display screen, and is equipped with special Qingjiao software developed by our company (the operating system supports Chinese/English bilingual display). “Self-taught programming” is easy to operate, intuitive and easy to learn, and has complete functions. It can simultaneously complete various profile welding angle facades, outer corner bevels, outer corner elliptical arcs, upper and lower plane welds, inner corner inner plane welds, sealing strip grooves and internal Comprehensive cleaning of flat weld areas. According to different profiles, 100 corner cleaning programs can be set and stored, which have the advantages of high precision, high efficiency and high degree of automation. It is a high-end and practical corner joint cleaning equipment for large and medium-sized PVC plastic door and window processing enterprises.

| Comprehensive corner cleaning time | 18s | Processing profile width | 20-180mm |

| Processing profile height | 20-180mm | Groove width | 3mm |

| Input voltage | 380V/AC | Groove depth | 0.3mm |

| input frequency | 50HZ | input power | 1500w |

| working pressure | 0.4-0.7Mpa | Air consumption | 50L/min |

| Main milling cutter speed | 2800r/min | Net weight | 500Kg |

| Dimension L×W×H | 1750mm×1000mm×1650mm | ||